The 25th China International Cement Technology and Equipment Exhibition grandly opened at the Wuhan International Expo Center. This exhibition attracted numerous preferred suppliers in the industry, spanning three days, showcasing the latest technologies, equipment, and solutions in the cement industry, promoting industry exchange and cooperation.

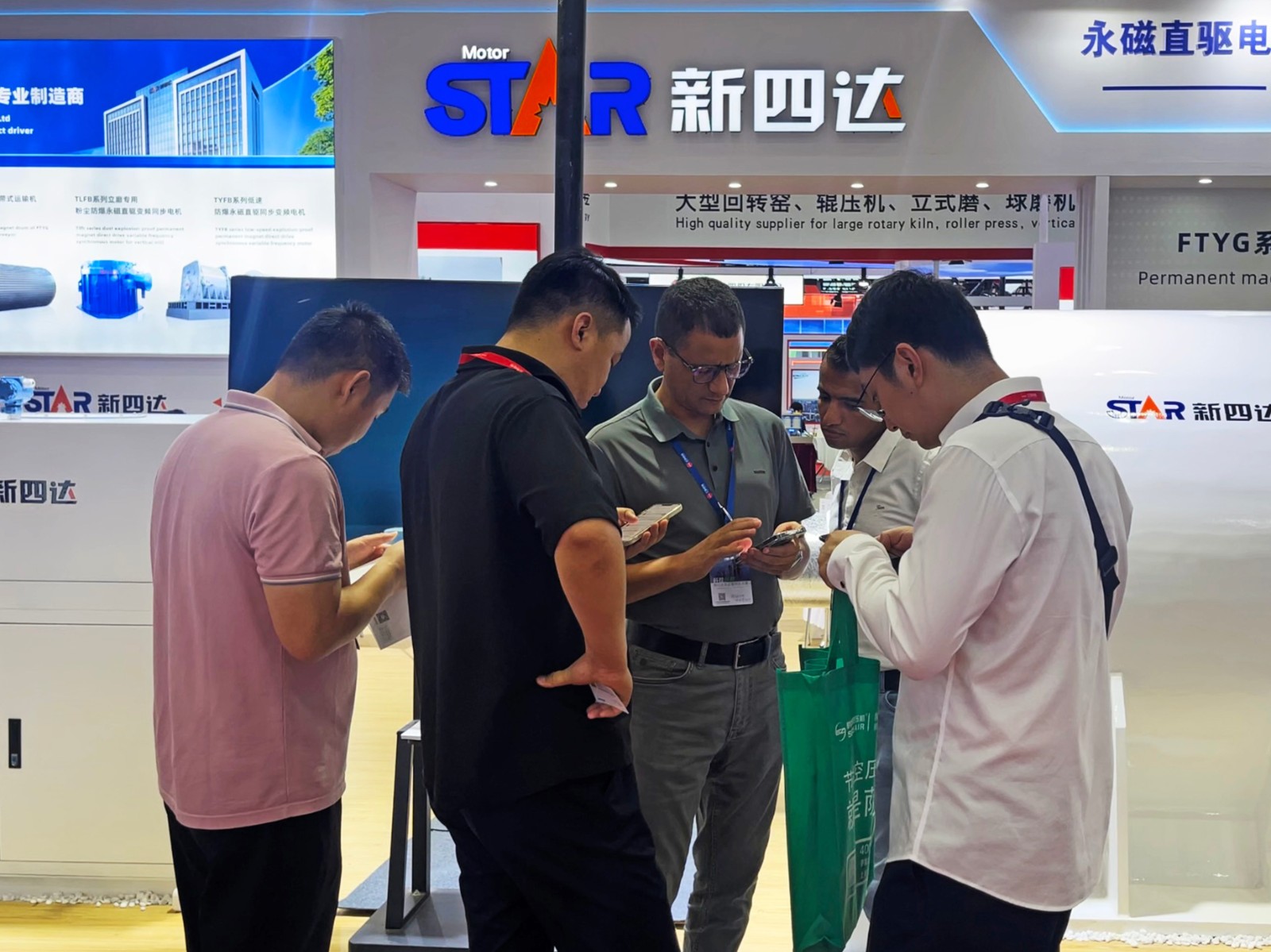

As one of the largest exhibitions in the global cement industry, this exhibition attracted over 150 cement equipment and technology enterprises from both domestic and foreign offices in China. It also attracted professional buyers from more than twenty overseas countries and regions including Russia, Turkey, Kazakhstan, Pakistan, India, Saudi Arabia, Germany, Belarus, Japan, the Philippines, Malaysia, Tanzania, Lebanon, Myanmar, Poland, Uzbekistan, Syria, C?te d'Ivoire, Yemen, and Vietnam, to jointly discuss the development trends of the cement industry, exchange cutting-edge technologies, and seek procurement and cooperation opportunities.

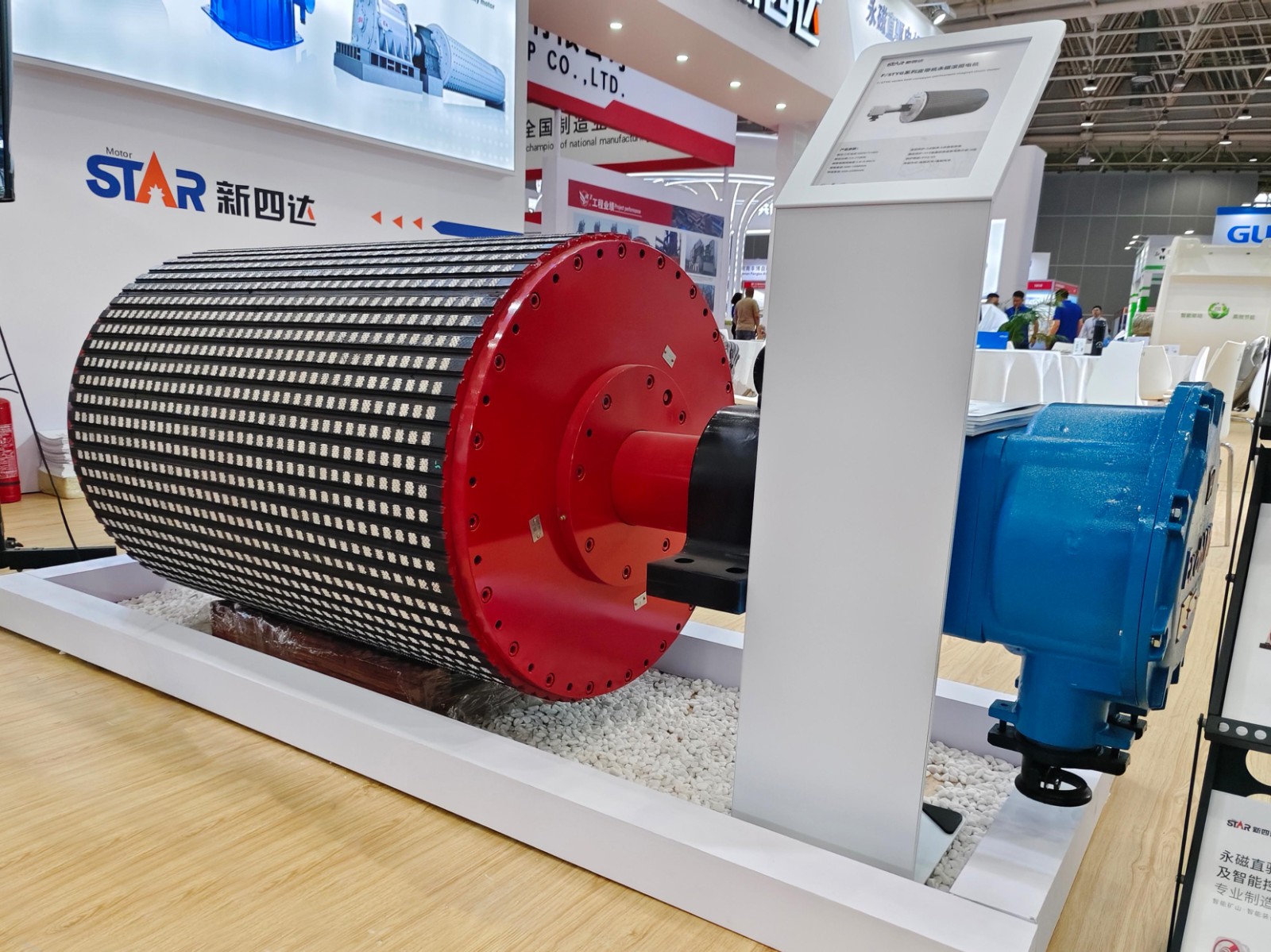

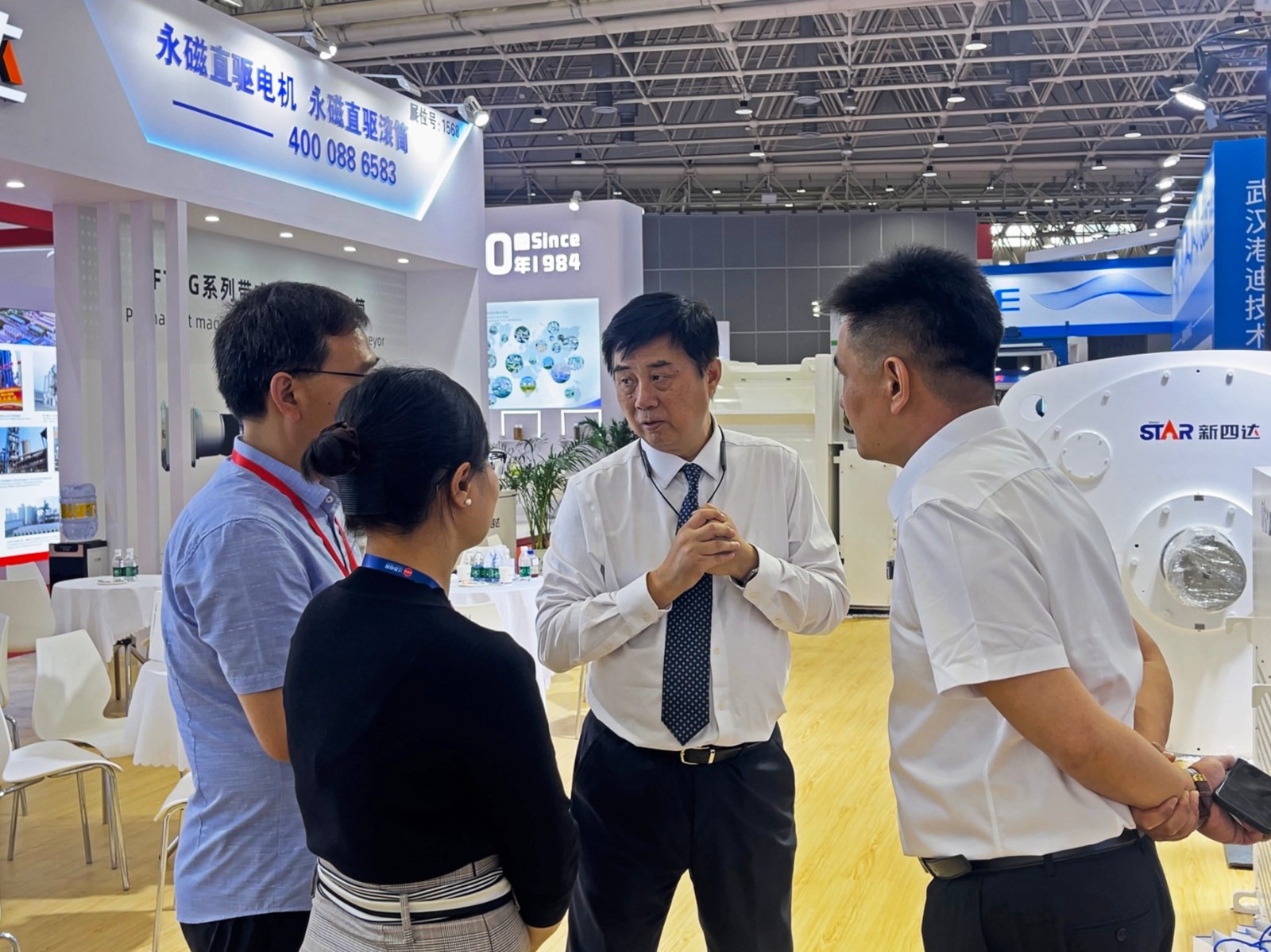

At this China International Cement Technology and Equipment Exhibition, enterprises from more than twenty countries and regions participated. Hebei Xinsida showcased the F/STYG series belt conveyor permanent magnet drum motor, TYB series explosion-proof permanent magnet synchronous variable frequency motor (low speed), TYFB series dust explosion-proof permanent magnet direct drive synchronous variable frequency motor, TYBSL series cooling tower fan permanent magnet direct drive motor, Z (F) SL series cooling system, and a comprehensive solution that attracted the attention of many guests on-site. In recent years, the cement industry has been continuously transforming and upgrading towards intelligent and green development, aligning with Xinsida development direction.

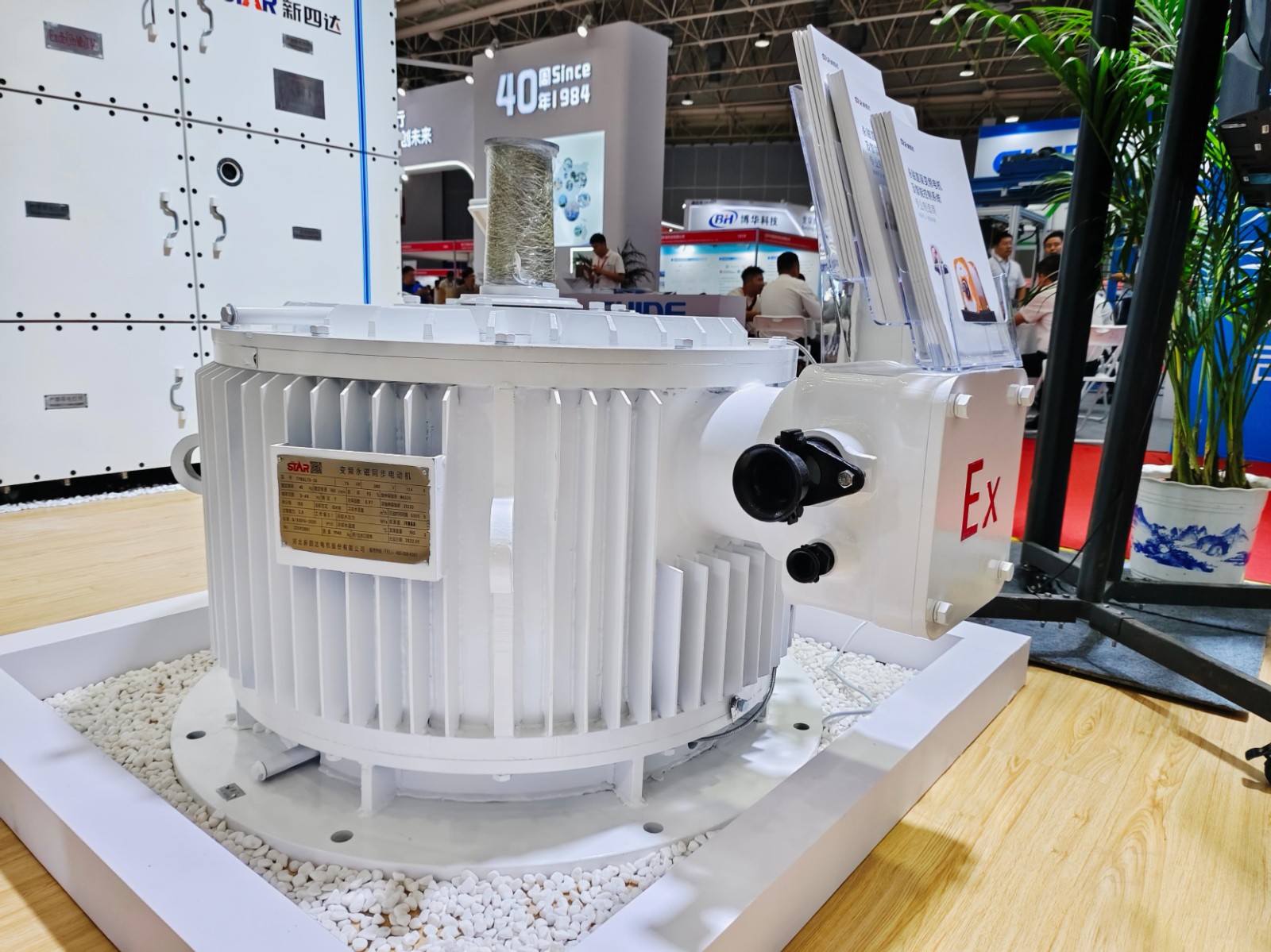

Hebei Xinsida Electric Motor Co., Ltd. showcased multiple products at this exhibition, among which the TYFB series dust explosion-proof permanent magnet direct drive synchronous variable frequency motor attracted much attention. This device is a newly developed permanent magnet direct drive synchronous motor targeting the low-speed, heavy-duty equipment market demand, specifically designed for the drive and transmission links of mechanical equipment. Based on the unique electromagnetic characteristics and vector control methods of permanent magnet motors, combined with the characteristics of power supply and system cost-effectiveness, a complete set of drive and control system solutions was developed, optimizing motor design, reducing material costs, and decreasing energy loss, resulting in significant economic benefits. The elimination of mechanical reduction devices greatly reduces the maintenance workload of the equipment while enhancing the operational reliability and sustainability of the motor, reducing maintenance costs after investment operation. Therefore, this product garnered numerous accolades and cooperation opportunities upon its debut at the exhibition. Thanks to the team efforts and to every visitor for their recognition.

Cement industry solutions, ball mill: TYFB series dust explosion-proof permanent magnet direct drive synchronous variable frequency motor, reconstruction advantages: address faults caused by the reducer/ eliminate the reduction in system efficiency due to the efficiency loss of the reducer, reduce equipment footprint, motor operating parameters monitored more timely, equipment operation more reliable; increased monitoring methods, reduced inspection workload. Belt conveyor: F/STYG series belt conveyor permanent magnet drum motor: improved equipment reliability, resolve issues such as oil leakage due to reducer and liquid coupling failures, excellent starting performance under load, flexible starting and stopping under heavy load, improved equipment reliability, reduced failure rates, extended equipment lifespan. Elevator: TYDT series elevator permanent magnet direct drive variable frequency synchronous motor, reconstruction advantages: motor center of gravity closer to the elevator shell, higher system stability, improved equipment reliability, address issues such as oil leakage due to reducer and liquid coupling failures, eliminate the reduction in system efficiency due to the efficiency loss of the reducer.

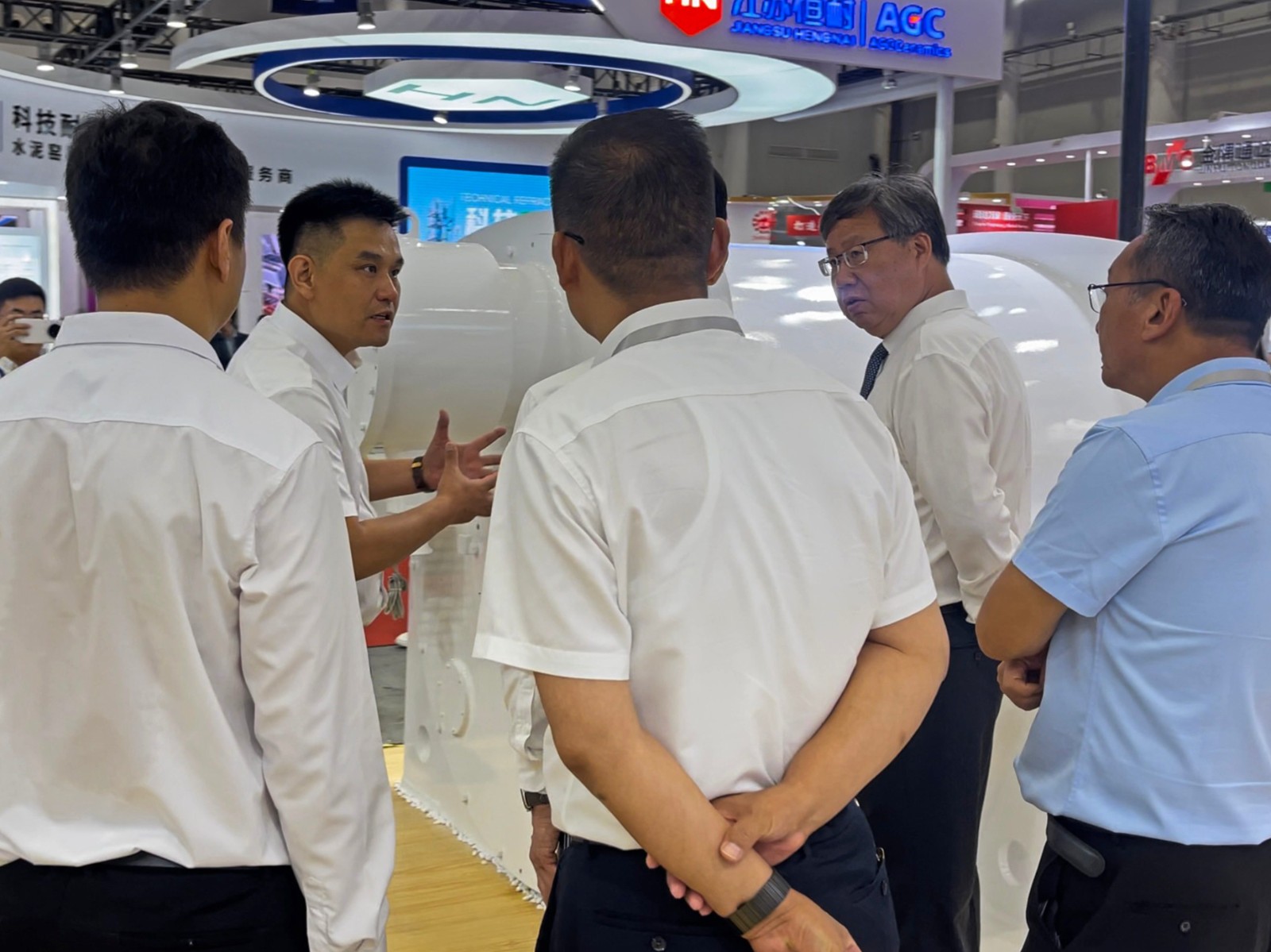

CEMENTTECH 2024 not only brings new technological innovations and market opportunities to the cement industry but also injects new momentum into our future development. We will take this opportunity to continue to deepen our efforts in the cement equipment field, contributing more wisdom and strength to the prosperity and development of the industry.

This international cement exhibition is not only a window to showcase the latest cement technology and products but also an important bridge to promote international exchange and cooperation. Through such grand events, we look forward to further promoting innovation and development in the global cement industry, jointly welcoming a brighter future.